Our UV systems for curing coatings, even on heat-sensitive substrates, offer customised converting services for your surface finishing. IST's UV systems create sophisticated effects, such as adhesive cross-linking, siliconisation, matting or hard coating. We have further developed our technology so that optimised nitrogen and oxygen consumption results in a positive energy balance.

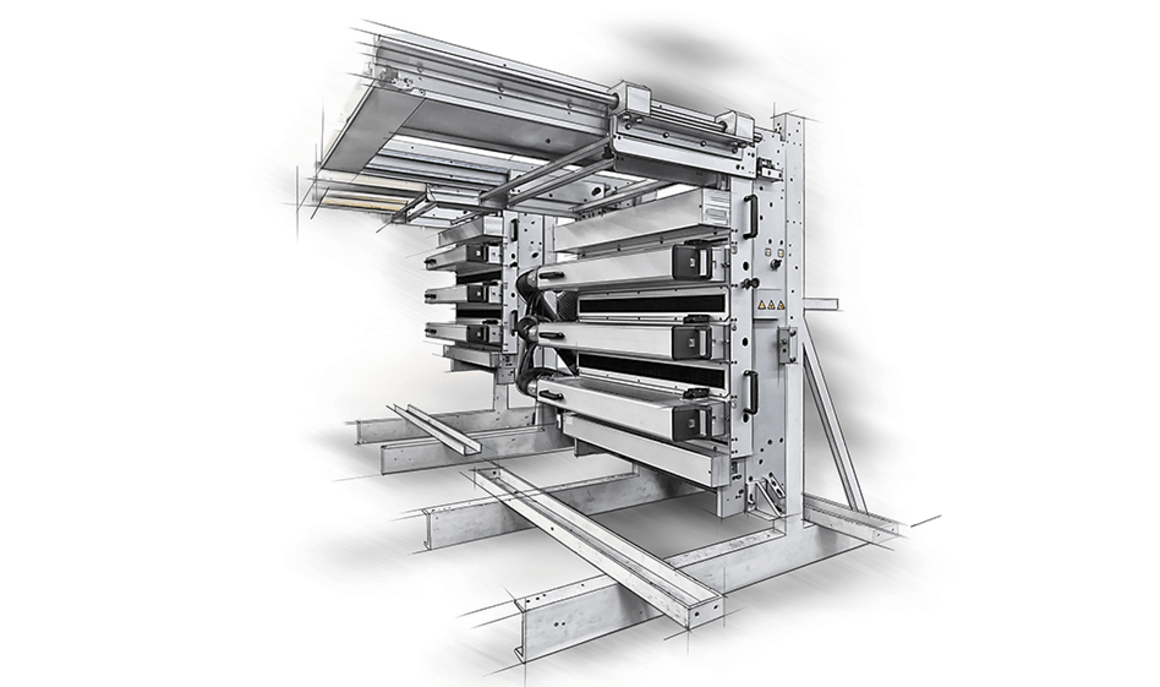

Whether paper, films or PVC plastics. With our expertise, we will find the right installation solution for your new and existing systems.

Our customised surface curing solutions are suitable for substrate types such as films, paper or PVC flooring when matting, siliconisation or UV-curing adhesives are required.

We are the specialists for adhesive crosslinking, siliconisation, matting and hard coating. IST systems are extremely customisable and can be used individually for different types of curing and coatings - even on heat-sensitive substrates. If, for example, radical-curing silicones are used, inert gas (nitrogen) is used to achieve the appropriate cross-linking in oxygen-reduced operation. In the case of cationic-curing silicones, a so-called post-cure effect occurs and it is not possible to redirect directly to the coated and cured side. The distance between UV curing and the next deflection depends on the speed.

During adhesive curing, adhesives are formulated and cured specifically for the product.

Characteristic effects such as matting can also be achieved with our excimer technology. Microfolding offers opportunities for a special surface finish, particularly in the PVC flooring sector.

A matt surface can also be created and cured to the desired degree with our UV-based systems during pre- and post-curing by using light-curing lacquers that contain appropriate matting agents.

For scratch-resistant and robust surfaces, hard coating using film application offers optimum and long-lasting results.

Surface hardening with IST means attractive effects at low temperatures, easy integration into existing systems and a long service life at high production speeds - for reduced energy consumption during all production steps.