Discover the future of UV curing with FREEcure – the groundbreaking innovation heralding the next quantum leap in UV printing. This revolutionary technology sets new standards by allowing lacquers and pigment coatings to be formulated without photoinitiators or even in a photoinitiator-free manner.

The high-energy UVC light, exclusively available in the market, enables the direct cleavage of double bonds without the need for photoinitiators. Particularly for GMP applications, this system establishes new benchmarks – all without requiring inertization in a normal atmosphere.

Experience a dramatic reduction in the number of lamps needed for dose-intensive applications and be inspired by a future that demands fewer photoinitiators. FREEcure redefines the possibilities of UV curing, paving the way for a more efficient, environmentally friendly tomorrow.

Explore the prowess of a technology that renders photoinitiators obsolete and revolutionizes the world of UV printing. To bring your application to life, we eagerly await your contact. Your vision, our expertise – let's make it happen together. Reach out to us now and let the transformation begin!

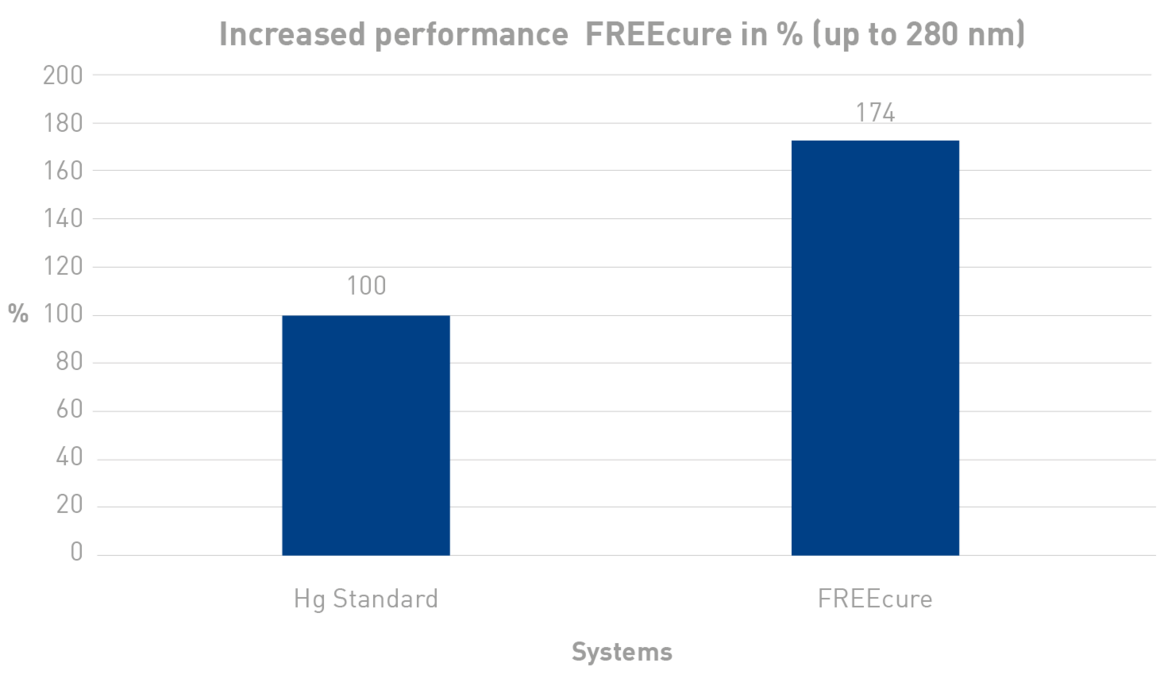

The BLK LAMPcure was developed for the highest industrial requirements. Compared to conventional UV systems, there is an extraordinary increase in drying performance with the FREEcure. This means more productivity at reduced operating costs. Based on the proven IST UV system BLK, a system was developed, resulting in an increased performance of more than 70% in the process relevant UVC spectral range. This was achieved by a coordinated package of measures including the following points: