Many drying processes require the release of the solvent. The best-known solvent is water. To accelerate proceedings, energy in form of heat is supplied. This is called an evaporation of water.

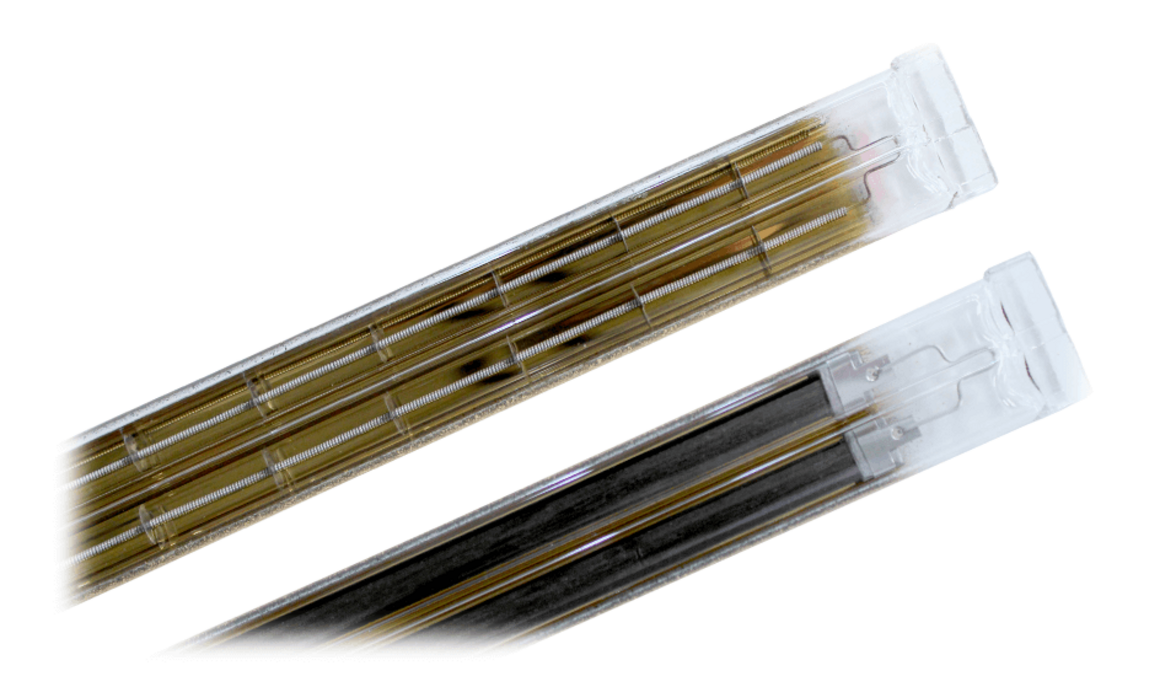

A combination of radiation in the infrared area and warm air aims to bring energy into the wet water film that needs to be cured. The energy input causes the acceleration of the evaporation process, while a defined air circulation and extraction provide for the secure removal of the released water. Depending on the machine speed, the solvent content and the film thickness, a particular drying line and hence amount of energy is needed. The required energy can be pulled from different combinations of IR radiators, carbon radiators and warm air.

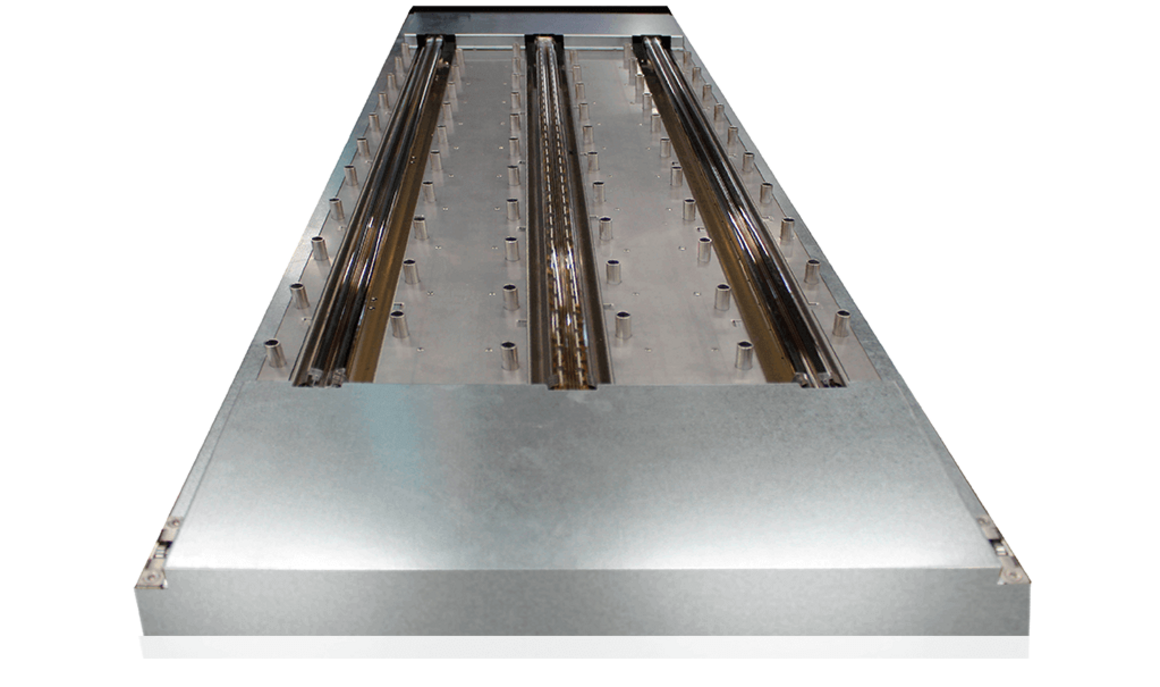

The W/IR dryer is completely erected in a cassette. Depending on the spatial conditions, there are different standard widths available. Individual adjustments are possible. For a fast lamp change, the cable clamps of the IR radiators are accessible from below.

| Width (mm) | Nozzles | Radiators |

| 320 | 4 | 2 |

| 520 | 6 | 3 |

| 720 | 8 | 4 |