Narrow web

Highest quality for narrow web applications

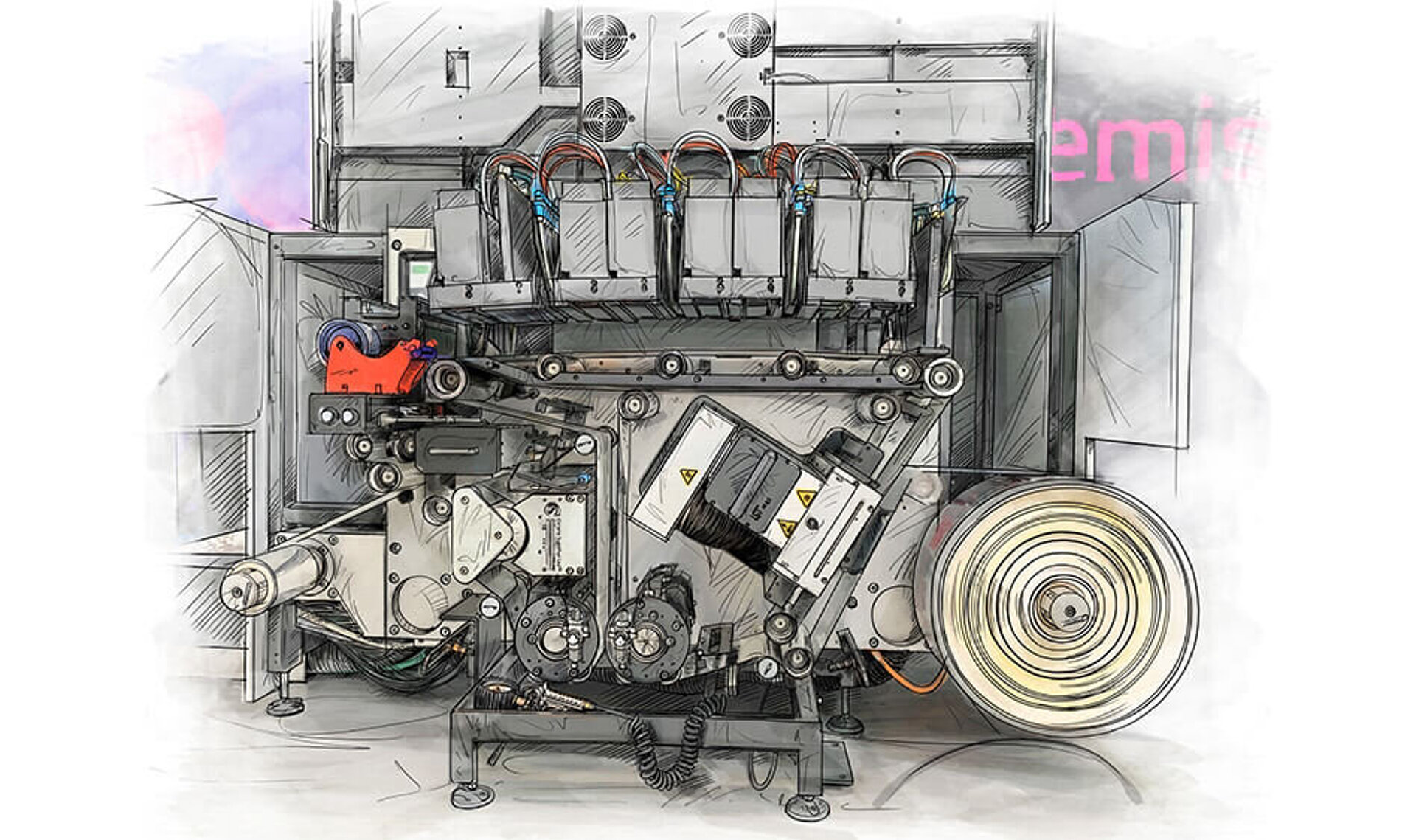

In the production of high-quality labels for cosmetics, medicine, chemicals and retail, users utilise various printing technologies to produce labels of all kinds, from holographic jewellery labels to food labelling.

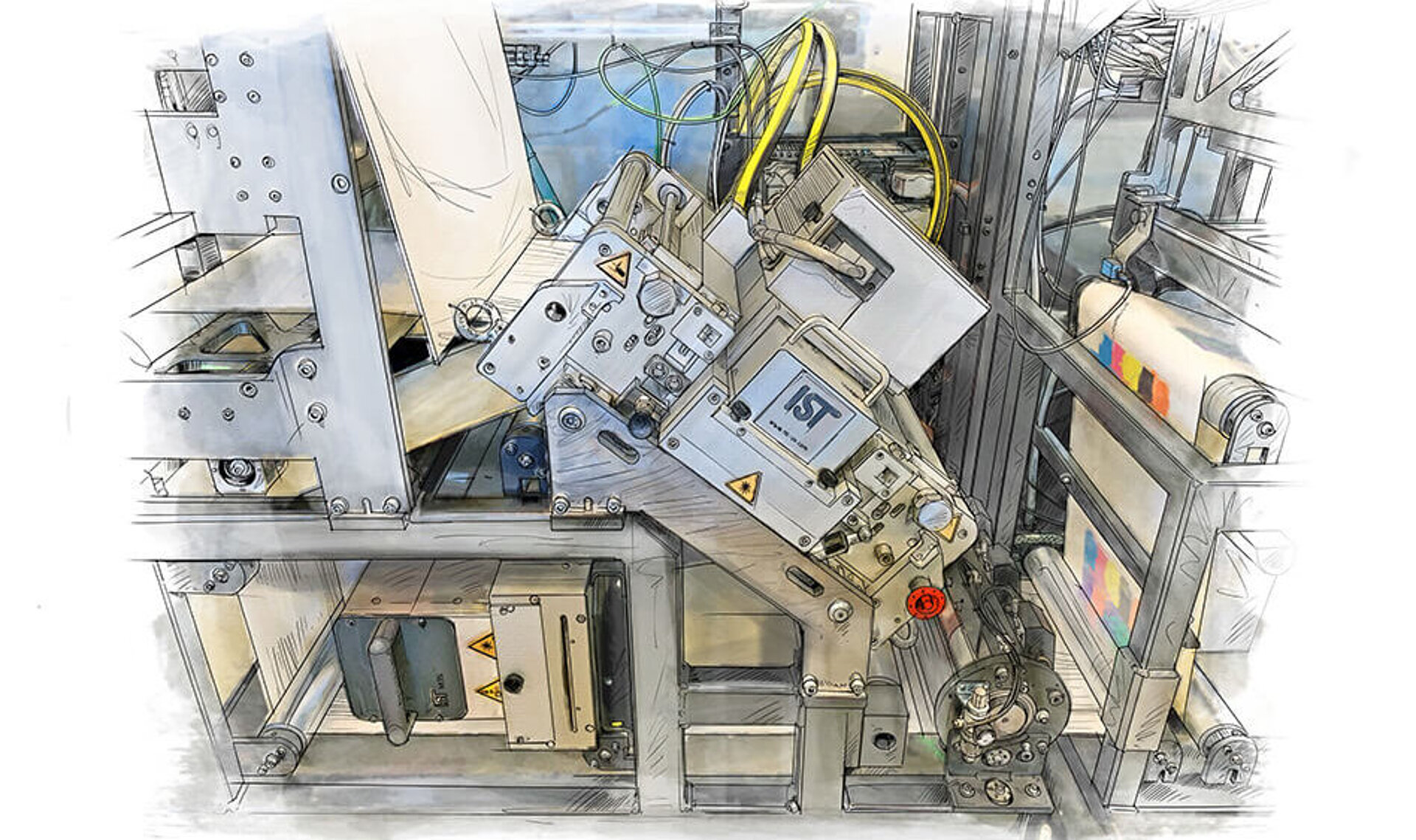

LED UV curing in particular is becoming increasingly important, as it has a number of advantages over conventional mercury vapour lamps. They are energy-efficient, emit less heat and have a longer service life, which reduces maintenance costs. The higher production speeds, better print quality and substrate compatibility are constantly increasing customer demand for more environmentally friendly web printing with LED UV curing.

Benefit from our decades of experience and the successful implementation of hundreds of installations in new and used presses from all leading press manufacturers worldwide.

Our UV technology is ideal for all paper labels, self-adhesive labels and monofoils for in-mould, wrap-around and shrink sleeve labels and has been specially developed for narrow and medium web printing processes, including flexographic printing, offset printing, screen printing, letterpress, gravure printing, pad printing, inkjet printing (digital printing inkjet), cold foil stamping and hot foil stamping.

Digital inkjet printing as well as modular and expandable all-in-one hybrid solutions in combination with classic offset and flexographic printing processes are becoming increasingly important in the efficient production of all types of labels in small and medium-sized print runs.

Attractive designs are becoming increasingly important, not least for reasons of competitive differentiation.UV matting is used to advertise packaging and its labelling and to highlight innovative functionalities.

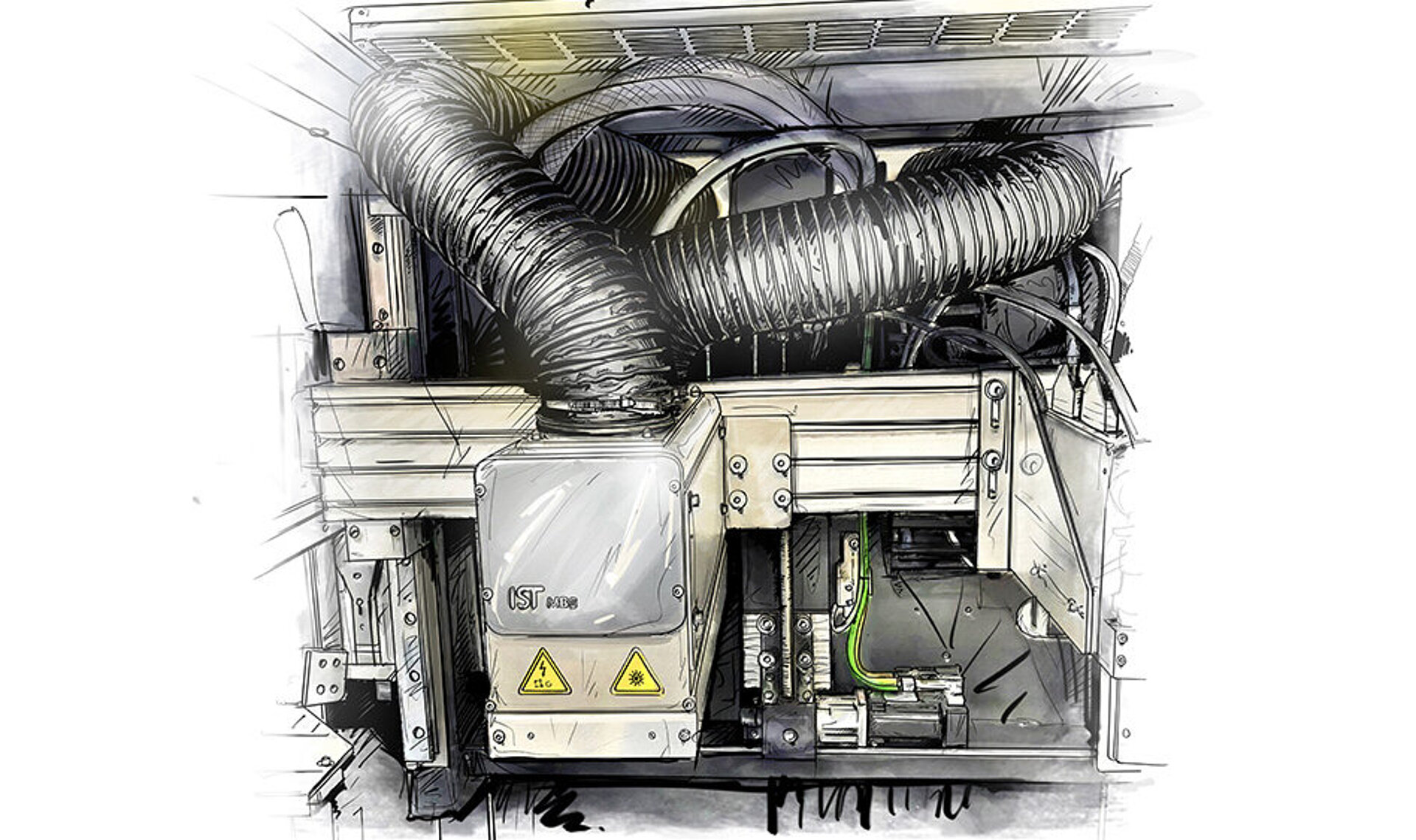

Optimised airflow routing and the use of highly transmissive quartz glass panes guarantee effective heat management in the UV system and throughout the entire printing or coating booth. By using special supply air assemblies, the supply air required for cooling the unit can be drawn in from outside the customer's booth. This prevents unwanted air turbulence, suction or heat loads from occurring inside the closed booths.

In addition to short curing times for immediate further processing, the UV system solutions enable high mechanical and chemical resistance as well as attractive effects in terms of gloss and colour.

By using the latest switching and control technologies, both conventional UV lamps and LED UV systems and UV HYBRID system solutions can be fully integrated into existing customer and machine control systems. Depending on requirements, IST lamp and LED UV system solutions can be combined in a flexible and user-friendly manner.

Get in touch today to discuss tailoring an appropriate and personalized IST UV system solution for new equipment, upgrades, and any unique customer needs.