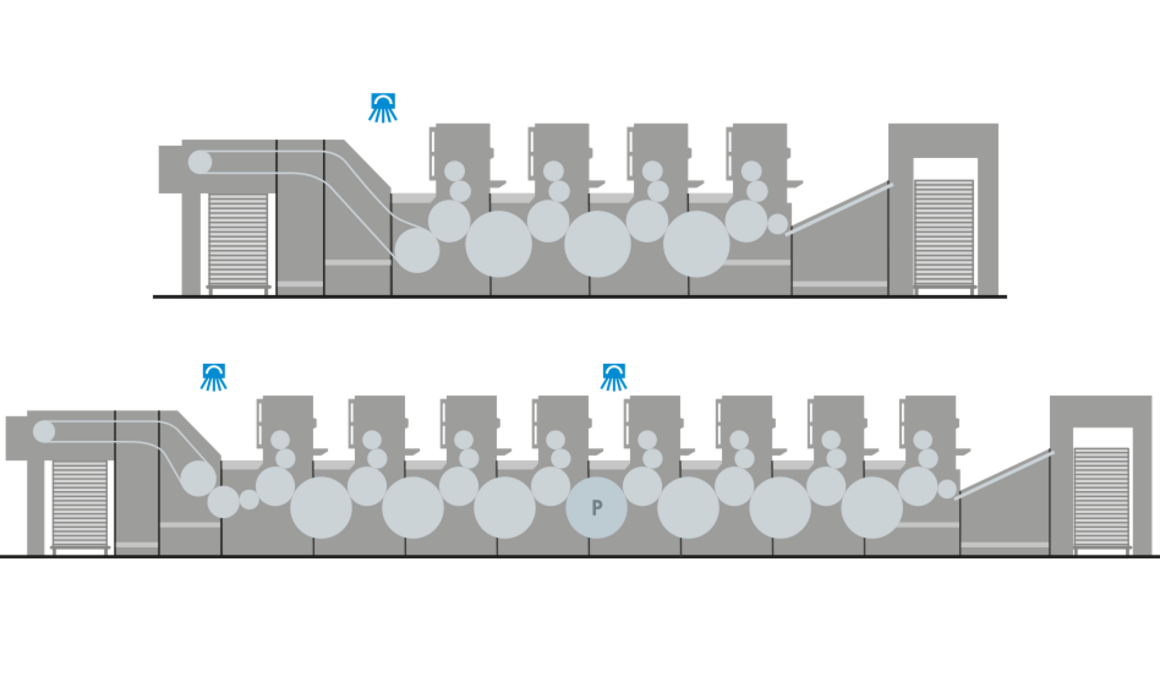

The LE UV system has now made it possible for all commercial printers to benefit from the advantages of energy-minimised drying - at low investment and operating costs! Just one dryer is required in the machine for all standard commercial printers. For perfecting presses, a dryer is additionally used before the perfecting device.

For all standard commercial printers, just one dryer is required after the last printing unit.

For perfecting presses, a dryer is additionally used before the perfecting device.