EXIcure

For perfect surface finishing

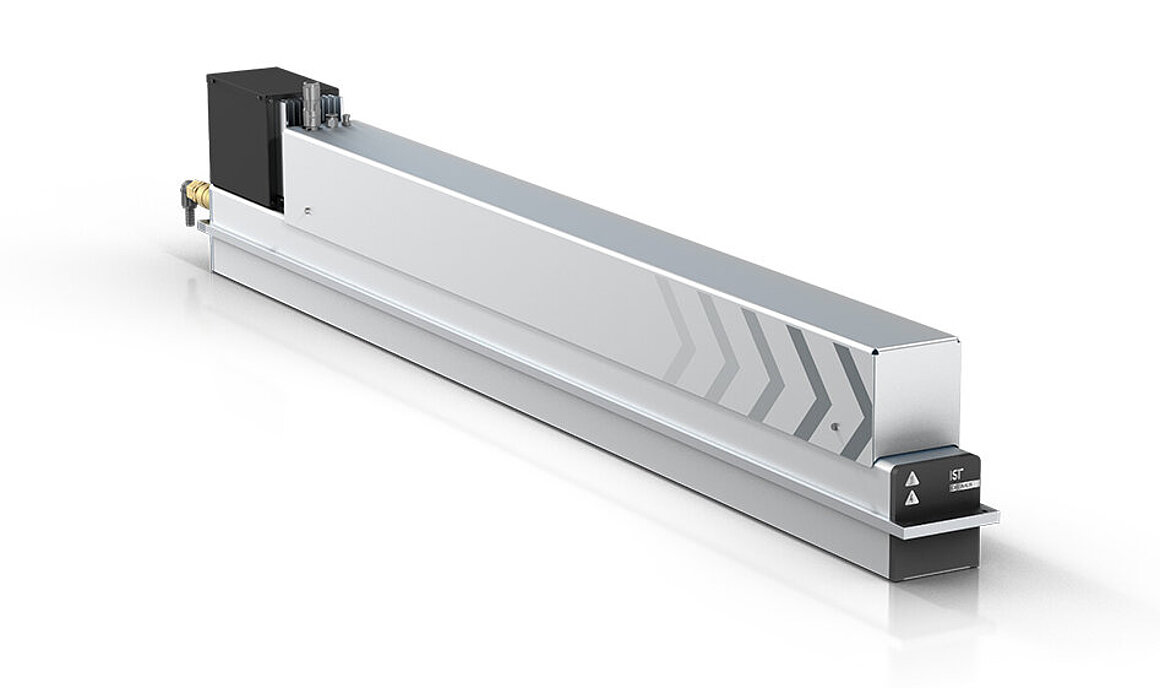

Discover the future of surface treatment with the Excimer, which is perfectly suited to the requirements of the wood and flooring industry with a working width of up to 4 meters. This groundbreaking technology sets new standards through the efficient use of excimer beams with an impressive width of 4 meters.

With a wavelength of 172 nm, the excimer transforms surface structures perfectly - without the use of matting agents in the paint. This creates matt surfaces with a gloss level of less than 5 gloss, which are hardened by the polymerization of short-wave excimer beams. The result is an abrasion-resistant surface with an anti-fingerprint coating and a particularly soft touch.

Through intensive research and development, it has been possible to achieve seamless integration, which enables an extended irradiation area without edge and streak effects. This allows existing production systems to be optimally utilised and productivity to be significantly increased, leading to a considerable increase in matt surfaces with existing equipment. IST METZ offers these extended working widths.

The development of excimer technology with a working width of up to 4 metres by IST METZ opens up new possibilities for the flooring industry. It enables efficient and even surface finishing and sets new standards in the processing of large-area floor coverings.

Users of high-quality materials such as functional films, wafers or thin films know how important gentle surface treatment is. Conventional methods such as corona, atmospheric plasma and flame treatment can damage sensitive materials materials and lead to delamination or failure.

UV cleaning processes play an important role in the display and semiconductor industry. UV light with a very short wavelength (maximum value at 172 nm) is used to break up the compounds the compounds of organic substances. In addition, excimer treatment is a non-damaging process that can improve the wettability and chemical affinity of materials without damaging them. It is particularly effective on metal surfaces surfaces and allows chemical-free removal of filmic contaminants without damaging them. filmic impurities without generating electrical fields that could lead to damage. can lead to damage. The result is a clean surface.

The modification of surfaces serves to improve the surface tension for better wettability. better wettability. Wettability is measured via the contact angle.