UV curing for cosmetics

UV technology for surface finishing of cosmetic parts

UV and LED UV systems allow coatings to be cured quickly, efficiently and with outstanding durability. This not only ensures flawless results and a long product life, but also optimises production processes. Coatings and finishes on plastic parts are cured in a wide range of applications to achieve specific properties such as scratch resistance, a high-gloss appearance or decorative surface finishes. Thanks to our many years of experience in UV technology, we offer customised solutions for the most demanding requirements. UV curing is also particularly environmentally friendly, as it does not use volatile organic compounds (VOCs) and fulfils the highest quality and sustainability standards.

When coating small cosmetic parts, such as lipstick tubes, an attractive appearance and high resistance to daily wear and tear are crucial. UV coatings are particularly impressive due to their exceptional scratch resistance. Depending on the requirements, solvent-based, solvent-free or water-based UV coatings are used for application and subsequent curing. Typical substrates include PVC flacons, PVC caps and glass flacons.

Metallised small cosmetic parts are often coated with protective and base coats that have already been successfully cured with UV systems. Proven UV technology offers excellent properties, but LED UV systems bring additional benefits to the process. Thanks to their monochromatic radiation, they avoid the entry of IR radiation, which means that heat-sensitive substrates can also be processed. At the same time, they enable very good paint curing without deforming the parts. This allows the use of thinner material thicknesses, which not only saves material but also reduces costs.

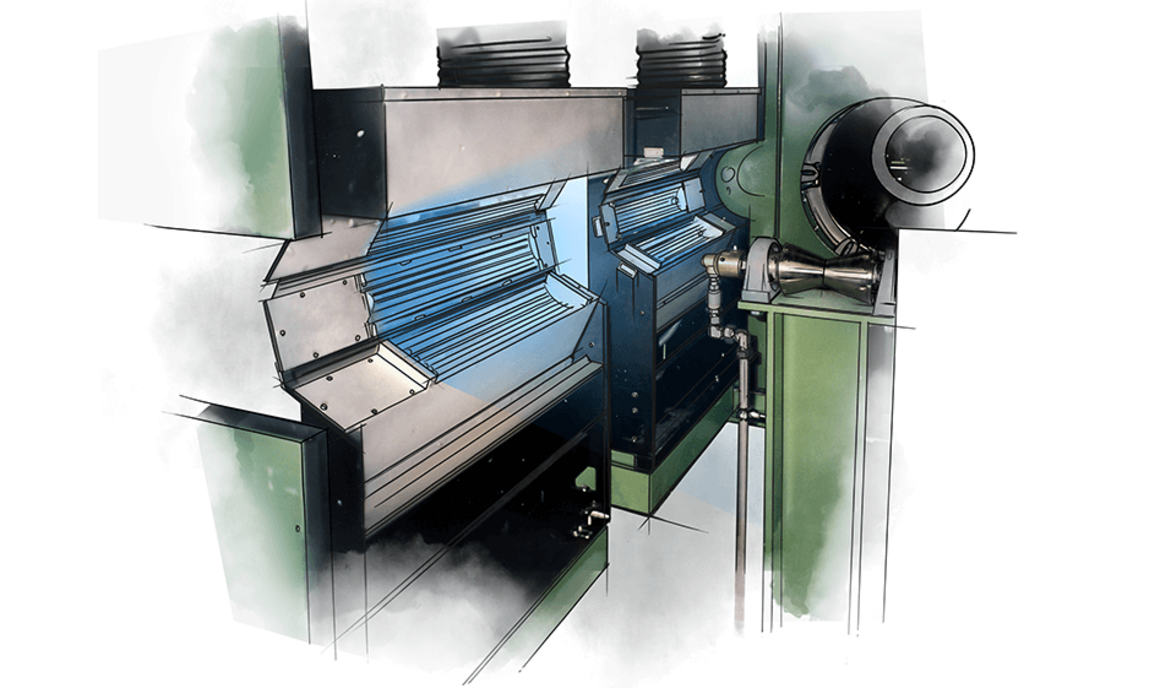

The special arrangement of our UV systems enables the flexible curing of a wide variety of geometries - both partial and full-surface. Our technologies offer a number of convincing advantages:

These advantages make our systems the ideal choice for demanding coating processes.