UV curing for coil coating

UV technology for processing coils

Coil coating is a continuous process in which metal strips such as steel, aluminium, stainless steel or wires are coated and then cured. For this demanding process, we supply specially developed UV drying systems (UV systems) that are optimally tailored to the requirements of the coil coating industry.

Our portfolio includes state-of-the-art technologies such as LED UV, UV and excimer systems, which have been specially developed for curing pre-coated thin sheet metal products. These innovative technologies are not only efficient, but also particularly environmentally friendly – thanks to the use of solvent-free 100% systems or water-based coating systems. This complies with the requirements of the VOC Directive and makes their use particularly sustainable. In addition, the low energy consumption significantly reduces operating costs, making UV technology a sustainable and economical solution.

Compared to conventional drying ovens for water-based coatings, UV drying offers numerous advantages:

Our specially developed UV systems are ideal for coating stainless steel coils, steel coils, galvanised steel and wires. Typical applications include the curing of primers and top coatings, which provide reliable scratch protection, effective corrosion protection and durable anti-fingerprint surfaces. UV coatings are characterised by their exceptional resistance to scratches, chemicals and weathering. The UV curing process can also be carried out under inertised conditions with nitrogen to achieve the best results in quality and performance.

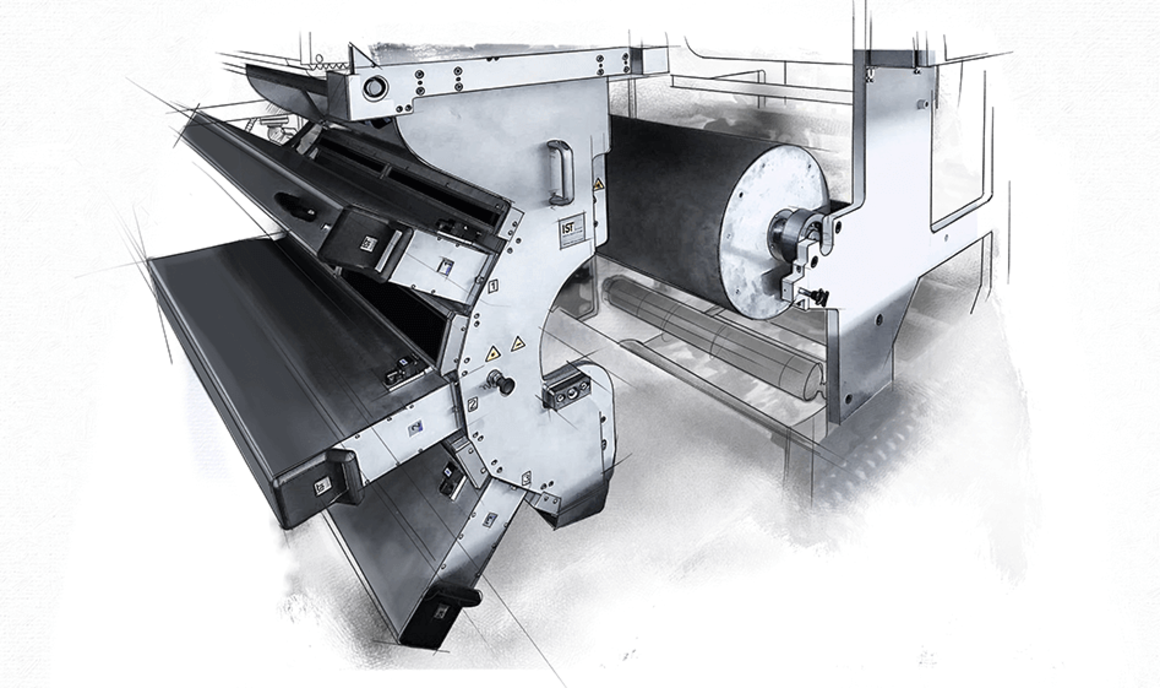

Robust steel wires are integrated to protect the UV lamps and reliably prevent damage. In addition, the UV dryers are designed so that they can be moved apart. This ensures optimum accessibility for maintenance work, servicing or in the event of a coil tear.

Thanks to our advanced UV technology, you benefit from fast production processes and highly efficient UV systems. The excellent UV efficiency of our UV systems not only contributes to significant energy savings, but also to easy integration into new or existing production lines thanks to their compact design. With our extensive expertise in the metalworking industry, we develop customised solutions that are perfectly tailored to your requirements and can be integrated into your production machines.