THERMOcure

Drying with warm air and infrared radiation

THERMOcure is a powerful, modular hot air and infrared drying system that has been specially developed for industrial applications. Through the targeted combination of IR radiation and convective hot air, THERMOcure enables fast, uniform and energy-efficient drying of water- or solvent-based inks, varnishes and coatings – in sheetfed offset as well as narrow web and label rotary printing.

The system is ideal for pre-drying, intermediate drying or final drying and can be flexibly integrated into existing production lines – both as a stand-alone solution and in combination with our UV or LED UV curing systems.

The exceptional performance of THERMOcure is based on the synergistic interaction of infrared radiation and warm air:

Compared to pure convection drying, THERMOcure works more efficiently, faster and with greater process stability, especially at high production speeds.

THERMOcure thus offers a future-proof solution for demanding industrial drying processes.

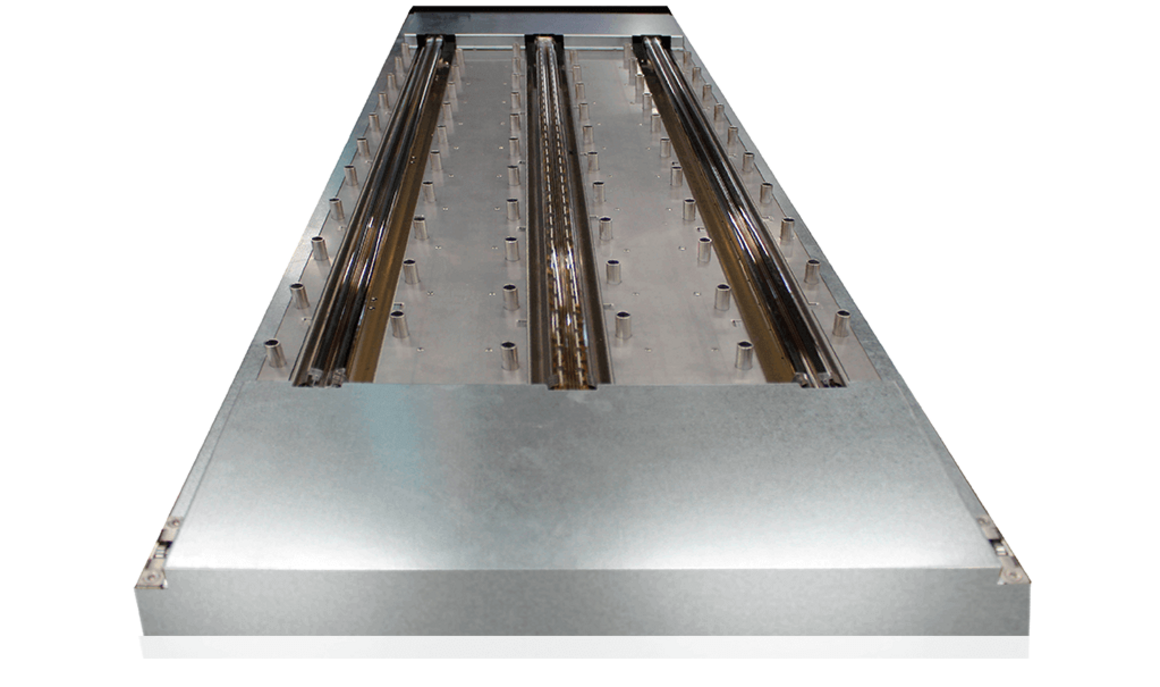

In sheetfed offset printing, THERMOcure is used as a fully pre-assembled cassette. The system is designed for different machine and space conditions and is available in various standard widths, which can be individually adapted as required.

IR drying in label printing is a proven and efficient solution for the rapid evaporation of water and solvents in water-based ink systems. In narrow web and rotary printing in particular, infrared drying ensures stable processes, high print quality and reduced downtime.

For narrow web and label rotary printing machines, THERMOcure offers specially tailored IR-based drying concepts that are designed to meet the requirements of water-based ink systems. In combination with UV curing, IR drying enables optimal pre- or intermediate drying, improves adhesion and increases the overall performance of modern label printing lines.

The IR emitter operates in the near-infrared range and is used to dry water-based inks and coatings in rotary label printing machines. The energy is applied directly to the wet coating film, which means that drying begins immediately after the respective printing unit. The system is process-stable at high web speeds and is particularly suitable for dense ink sequences and demanding substrate materials. The emitter can be exchanged as a replacement cassette for UV or LED modules, thus allowing flexible production configurations.

Features:

The combination of near-infrared IR emitters and warm air combines direct heating of the paint or lacquer film with efficient removal of the humid process atmosphere. While the film is quickly heated by IR, the warm air loosens the moist boundary layer on the surface and removes it via a mixture of laminar flow and specifically generated turbulence. This reduces the surface partial pressure, accelerates evaporation and compensates for adiabatic cooling effects through IR input. Compared to separately controlled IR and hot air stages, this results in a model increase in drying performance of around 30–50%, depending on layer thickness, air volume and temperature window. The system has been tested for label rotary printing machines up to 150 m/min and offers a wide process window with high production output.

Features: