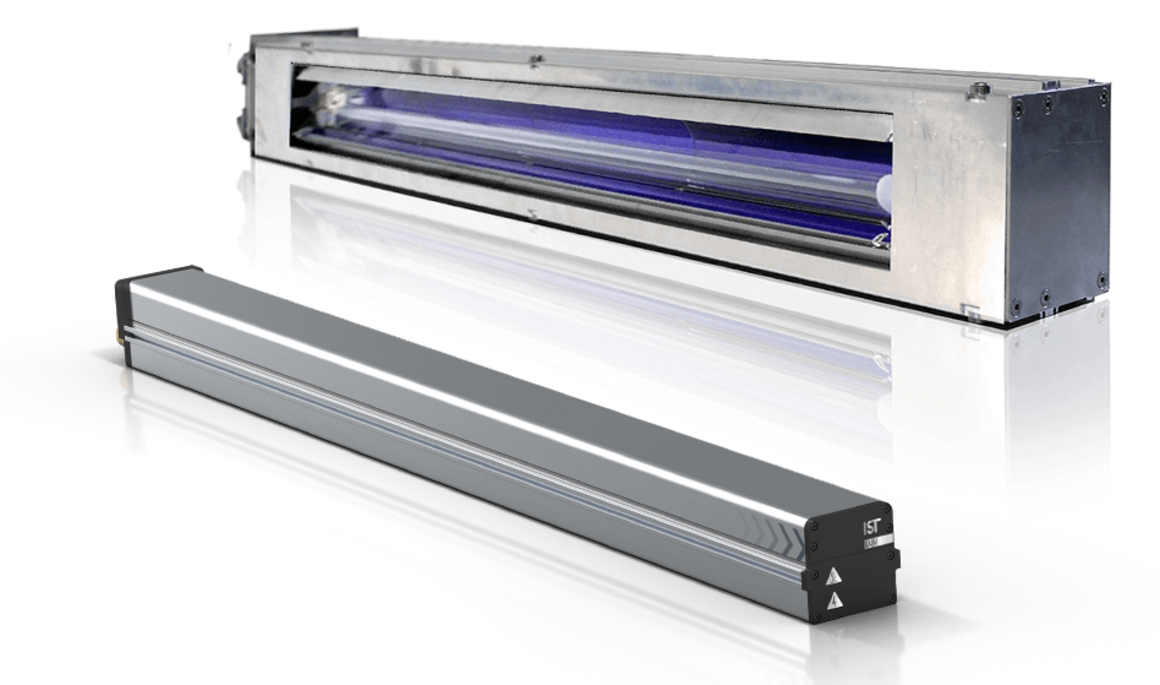

We not only aim to build the best UV and LED systems in the world, but are also convinced that our systems are the most economical of their kind in terms of total cost of ownership. With our worldwide partner and sales network, we offer you fast and uncomplicated service and support - also for the efficient LED and UV retrofitting of your systems. Find out more about our LED and lamp product portfolio and discover their individual benefits.

Our laboratory is available to determine the optimum system parameters for your products. With IST METZ's comprehensive after-sales service, we also offer you reactive and preventive service, with which the added value of your systems can be increased through optimisation, modernisation and individual measures.