UV curing for wood & wood based materials

UV curing for a variety of wood applications

UV curing offers numerous advantages in the surface treatment of wood and wood-based materials: it enables extremely fast curing, which significantly increases production speed and reduces energy costs. Thanks to the environmentally friendly, solvent-free coatings, high-quality, durable surfaces are created that are resistant to scratches, chemicals and moisture. The process also requires little space and offers precise process control, making it ideal for efficient and sustainable production.

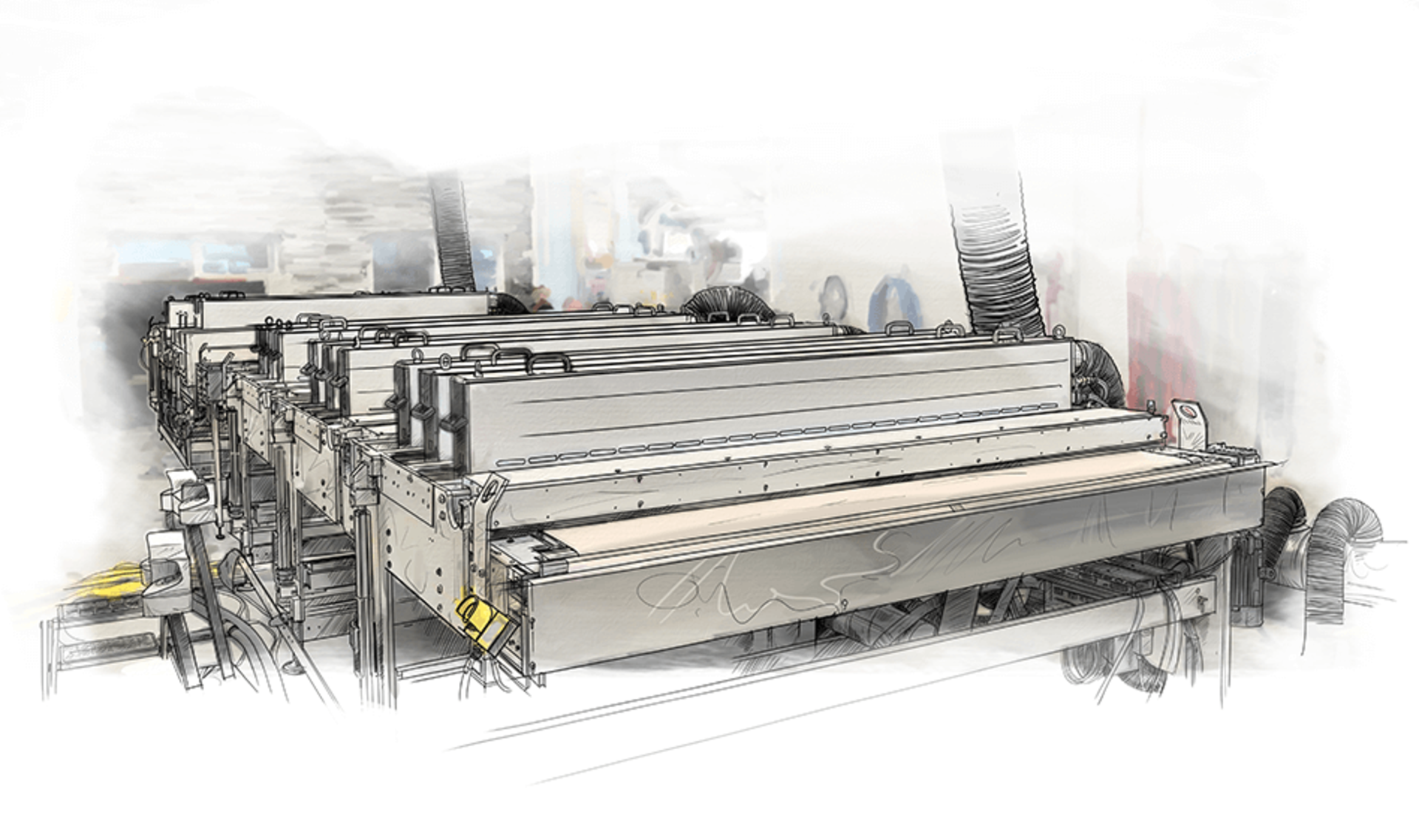

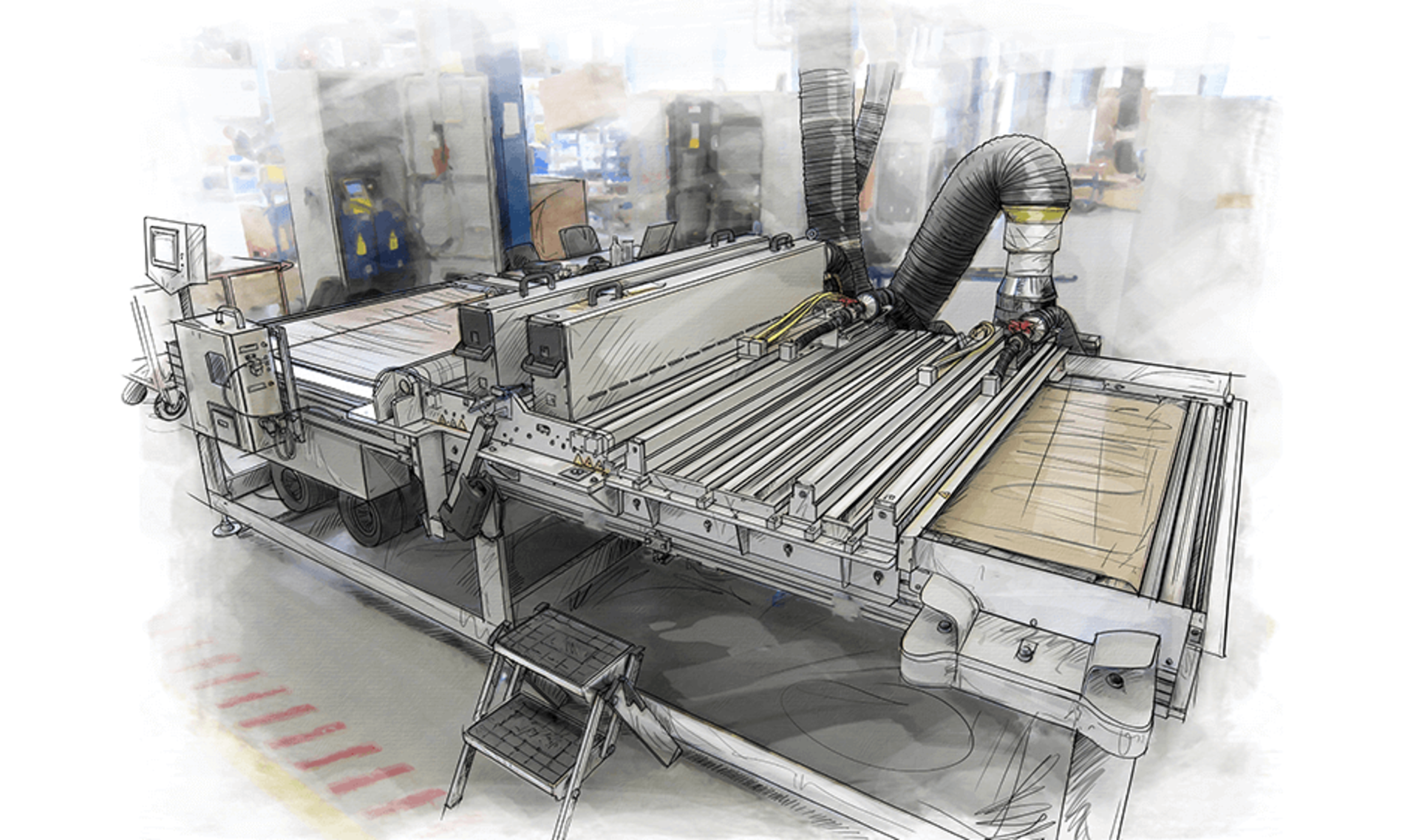

Discover our advanced UV systems for wood and wood-based materials that enable efficient wood finishing and wood coating. With our UV systems for wood, we offer customised solutions for surface coatings on wood that provide both protective and decorative properties.

Our UV systems offer versatile solutions for the wood industry, from partial curing (pinning) to final curing. We achieve first-class results with UV-curing finishes such as fillers, sealers and lacquers that have been specially developed for the requirements of wood and wood-based materials. Whether for 2D or 3D applications, our systems are ideal for coating chipboard, MDF/HDF fibreboard and natural real wood. Especially for parquet and wooden floors, but also for the finishing of mouldings, profiles, doors and windows, we ensure a high-quality, long-lasting surface.

Our UV systems for wood-based materials are characterised by low temperature exposure and reduced energy consumption. Thanks to our UV wood coating technology and long-standing network, we offer industry-leading expertise in wood finishing and coating. Our range includes air- or water-cooled UV systems that have been specially developed for the requirements of wood finishing.

We have the solution for your individual requirements for wood coating and finishing. Discover the compelling advantages of choosing our UV solutions.