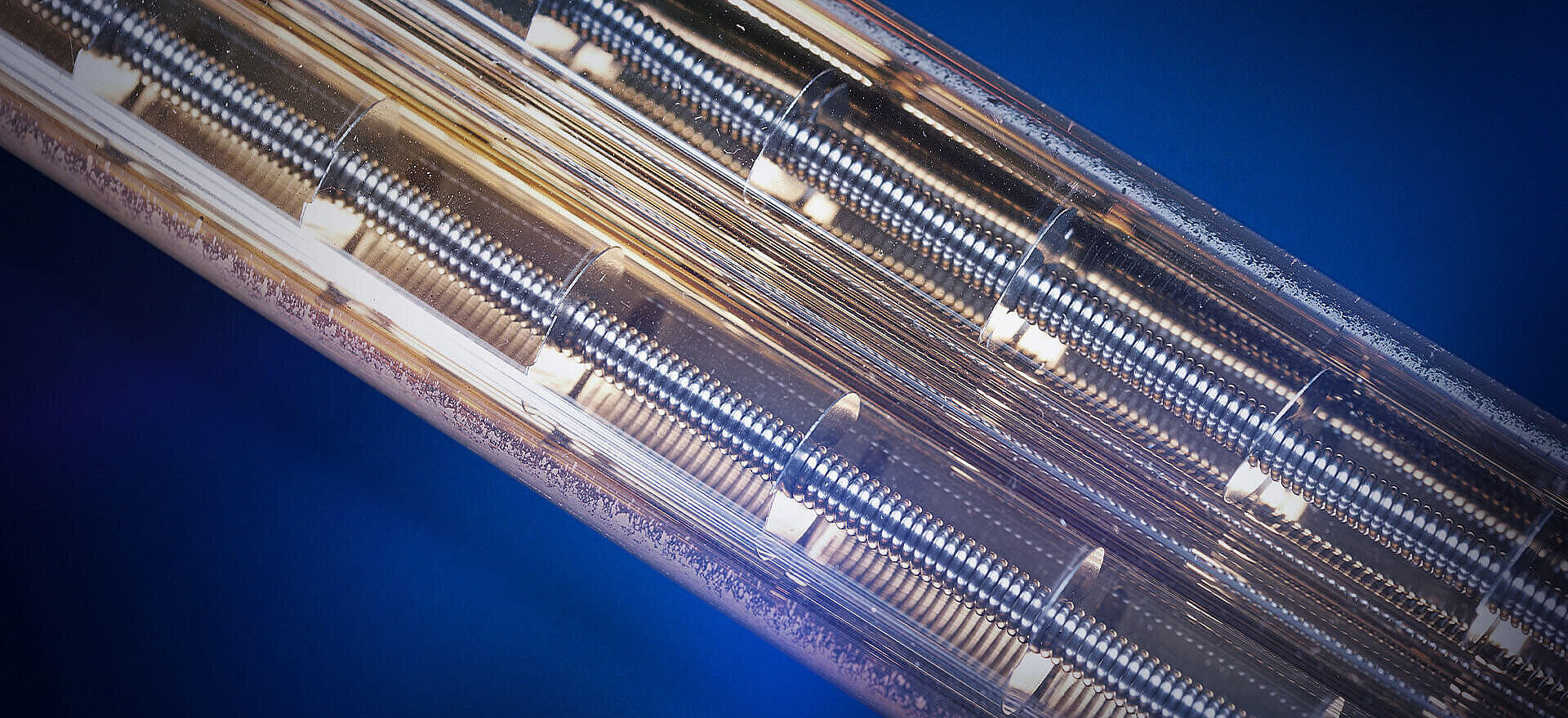

W/IR technology

Hot air & infrared for industrial drying processes

IST METZ's W/IR technology is a powerful and energy-efficient solution for thermal drying in industrial processes. The intelligent combination of warm air (convection) and infrared radiation (IR) allows water and solvents to be removed reliably and evenly from paints, varnishes and coatings. The process is ideal for applications where reliable drying is required – regardless of subsequent curing or cross-linking steps.

Unlike UV or LED UV systems, W/IR technology is not based on a chemical reaction, but on the physical evaporation of liquid components. This offers maximum process reliability, high flexibility with different substrates and precise adaptation to individual production requirements.

With over 45 years of experience in UV, LED UV and thermal drying processes, IST METZ has comprehensive process expertise and develops tailor-made solutions for demanding industrial drying tasks.

Contact us to find out whether W/IR technology is the optimal solution for your application.

The combination of warm air and infrared combines two physically different, complementary principles of action:

Removal of evaporated media

Only the interaction of both components enables controlled, uniform and reliable drying – even at high production speeds.

W/IR technology is particularly suitable for processes in which:

Typical materials:

W/IR technology is not an alternative, but often a supplement to UV or LED UV processes – especially in hybrid production lines.

| Technology | Principle of operation | Typical application |

|---|---|---|

| UV / LED UV | Photochemical cross-linking | 100% solid UV inks and coatings |

| Hot air | Convection | Classic wet coatings |

| IR | Direct heat input | Accelerated evaporation |

| W/IR | IR + convection combined | Efficient thermal drying |

The technology is used across a range of industries, including:

The technology can be flexibly adapted to production speed, layer thickness and substrate.

IST METZ does not view W/IR technology in isolation, but rather as part of integrated system solutions. In many applications, the greatest added value is achieved by combining:

The result is highly productive, energy-efficient and stable production processes.

Based on W/IR technology, IST METZ develops individually configurable drying systems that are precisely tailored to the respective process.

You can find out more about specific system solutions on the relevant product pages, e.g. modular W/IR drying systems for industrial applications.