Numerous plastic products are printed with UV-curing inks or coated with transparent layers and then cured using energy-efficient UV systems. With our UV and LED UV systems, plastics can be precisely coated, bonded or metallised.

Either solvent-based, solvent-free or aqueous UV coatings are used for coating. By using UV systems in plastics processing, special effects such as a special high-gloss look can be achieved.

Both conventional UV systems and LED UV units are used for UV curing of cationic, radical or dual-cure adhesives for plastics. A wide range of applications can be realised with the systems, from spot bonding to large-area bonding.

Plastics are used in a variety of applications where UV curing plays a crucial role. From diffuser lenses, automotive interiors and household appliances to flower pots and mobile phone casings - UV curing enables durable and resistant surfaces. Safety-relevant products such as crash helmets, optical films, cannulas and optical lenses also benefit from the precise and fast curing processes with UV. In boat building, thermostats, displays, printed circuit boards, chips and smart cards, UV curing ensures efficient and high-quality processing.

When metallising plastics, the PVD (physical vapour deposition) process is used, in which a metal layer is vapour-deposited in a vacuum chamber. UV systems play a key role here by reliably curing UV primers or UV top coats, thus ensuring an even and resistant surface. This process is used for reflectors, small cosmetic parts and in automotive interiors and exteriors to apply decorative and functional metal coatings.

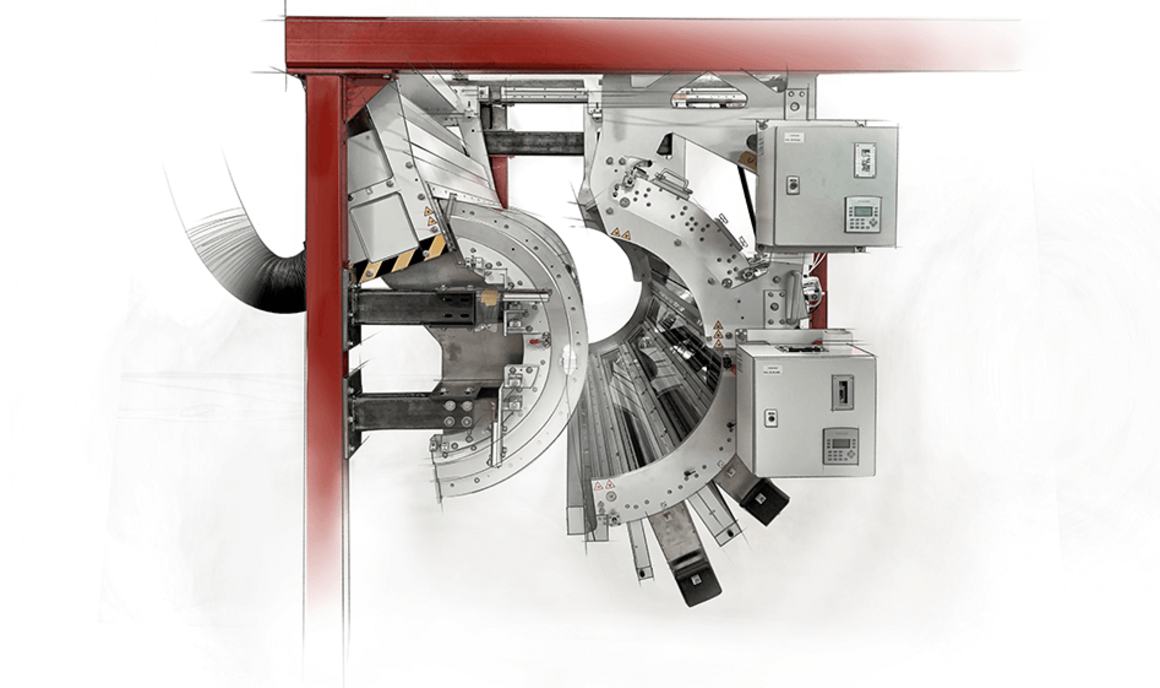

In the Converting division, we offer customised UV systems for various coating and cross-linking processes. These include UV siliconisation, the cross-linking of hotmelt acrylates and the coating of PVC flooring and decorative films. Our systems enable precise gloss level control with 100% UV coating systems, particularly for large-area applications such as PVC floor coating with working widths of up to five metres.

Our UV systems also offer maximum process reliability and efficiency when it comes to UV curing for silicones and UV coatings. In addition to the standard UV systems, inertisable versions are also available for this purpose, which have been specially developed for demanding applications. Our UV systems are used, for example, in the production of PVC flooring, double-sided adhesive tapes, decorative films for furniture, medical adhesive tapes and in the processing of adhesive materials, silicone coatings and hotmelt acrylates.

UV curing enables particularly fast and efficient curing of coatings on plastics. As the process only generates a small amount of heat, even heat-sensitive materials can be processed safely without causing deformation or damage. UV coatings fulfil the highest requirements in terms of appearance, scratch resistance and weather resistance. The short curing time increases production speed, reduces energy and operating costs and at the same time improves the surface quality and durability of the products.

We offer UV systems for finishing plastics - ideal for coating, bonding and metallising with conventional and LED UV units. Discover the versatile applications of our solutions.