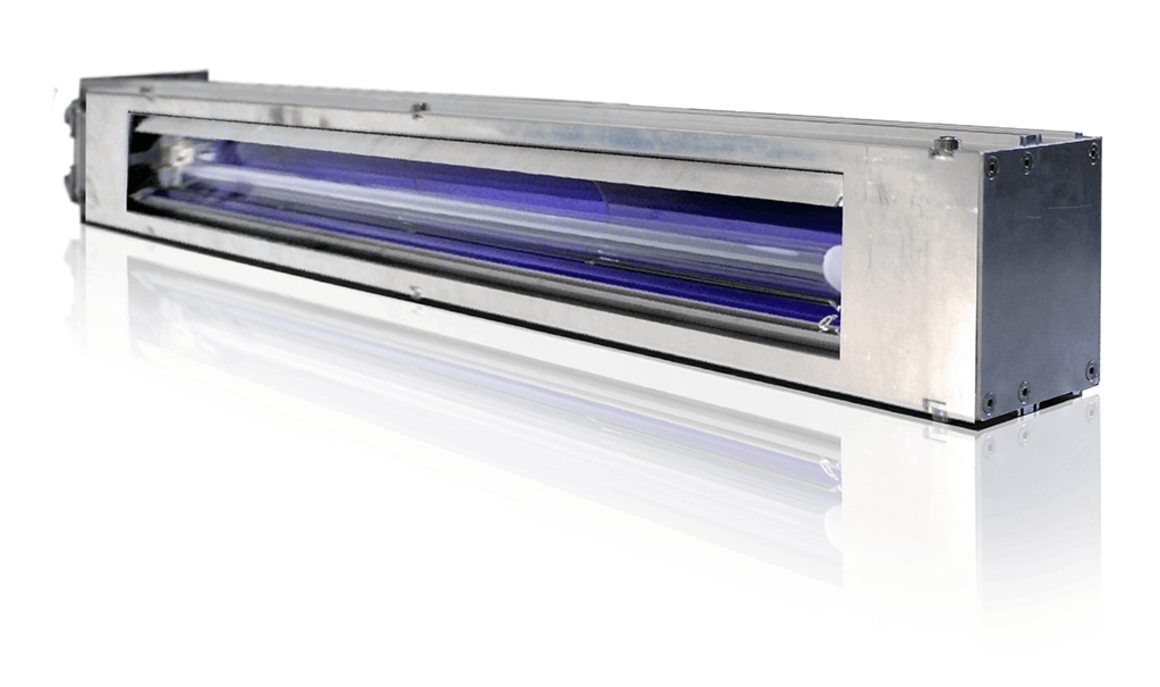

BLK S (water cooled)

Plug-in UV curing system für sheetfed printing

The UV sheetfed-drying system represents a further optimisation of our proven technology when it comes to output and energy usage. Only two individual plug-in modules with an output of 200 W/cm each are normally used for sheetfed end-of-press drying. The UV output generated is comparable with a common three-lamp system. Significant energy savings can therefore be achieved, depending on the application.

HotSwap technology enables the flexible use of BLK S and LUV systems in sheetfed printing. A BLK S system can easily be converted to a LUV system.